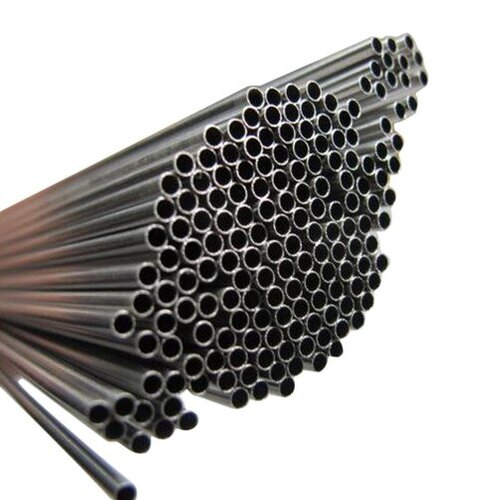

Hard Stainless Steel Capillary Tubes

Price 55 INR/ Meter

Hard Stainless Steel Capillary Tubes Specification

- Connection

- End open, seamless

- End Protector

- Plastic end caps

- Alloy

- Austenitic Stainless Steel

- Application

- Medical, Laboratory, Instrumentation, Chemical, Industrial

- Product Type

- Hard Stainless Steel Capillary Tubes

- Surface Finish

- Bright Annealed, Polished

- Material

- Stainless Steel

- Steel Grade

- 304, 316, 304L, 316L

- Type

- Capillary Tube

- Shape

- Round

- Standard

- ASTM, DIN, EN, JIS

- Grade

- ASTM A269 / A213 / A312

- Surface Treatment

- Hard, Annealed

- Technique

- Cold Drawn

- Thickness

- 0.25 mm to 2.5 mm

- Outer Diameter

- 0.3 mm to 8.0 mm

- Length

- Up to 6 meters or custom

- Tolerance

- 0.02 mm

- Color

- Silver/Metallic

Hard Stainless Steel Capillary Tubes Trade Information

- Minimum Order Quantity

- 100 Meter

- Payment Terms

- Paypal, Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1000 Per Month

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Hard Stainless Steel Capillary Tubes

Experience the transcendent durability of Hard Stainless Steel Capillary Tubes, acclaimed for their enviable corrosion resistance and exceptional hardness (HV 220-280). Engineered for high-pressure, harsh environments, these splendid tubes suit demanding applications in medical, chemical, laboratory, and industrial sectors. Available in ready stock or made-to-order, buyers can purchase custom sizes with seamless or welded construction-meeting ASTM, DIN, EN, and JIS standards. Boasting a temperature resistance up to 800C and bright polished finishes, each tube arrives bundled or boxed, with ends carefully protected for optimum integrity.

Special Features & Application Areas

Hard Stainless Steel Capillary Tubes are distinguished by superior hardness, seamless or welded construction, and exemplary corrosion resistance, making them ideal for use in medical instruments, laboratories, chemical processing, and industrial equipment. Offered in multiple grades (304, 316, 304L, 316L) and sizes, they provide primary competitive advantages with a high-pressure rating, precise tolerance (0.02 mm), and splendidly polished surfaces that ensure reliable, long-term performance in challenging environments.

Supply Ability, Delivery Time & Export Markets

With a robust supply capacity, these tubes are available for immediate arrival from ready stock or rapid fabrication for custom requirements. Delivery schedules are optimized through efficient logistics, and prompt quotations are provided upon inquiry. Catering to main export markets in India and internationally, distributors, exporters, and suppliers ensure seamless transportation and flexible packing. Each shipment arrives with guaranteed protection and compliance to global standards, matching customer demands with competitive speed.

Special Features & Application Areas

Hard Stainless Steel Capillary Tubes are distinguished by superior hardness, seamless or welded construction, and exemplary corrosion resistance, making them ideal for use in medical instruments, laboratories, chemical processing, and industrial equipment. Offered in multiple grades (304, 316, 304L, 316L) and sizes, they provide primary competitive advantages with a high-pressure rating, precise tolerance (0.02 mm), and splendidly polished surfaces that ensure reliable, long-term performance in challenging environments.

Supply Ability, Delivery Time & Export Markets

With a robust supply capacity, these tubes are available for immediate arrival from ready stock or rapid fabrication for custom requirements. Delivery schedules are optimized through efficient logistics, and prompt quotations are provided upon inquiry. Catering to main export markets in India and internationally, distributors, exporters, and suppliers ensure seamless transportation and flexible packing. Each shipment arrives with guaranteed protection and compliance to global standards, matching customer demands with competitive speed.

FAQ's of Hard Stainless Steel Capillary Tubes:

Q: How are the Hard Stainless Steel Capillary Tubes manufactured?

A: Hard Stainless Steel Capillary Tubes are produced using either seamless or welded processes, incorporating cold drawing techniques to achieve precise tolerance and superior hardness. The tubes are then bright annealed or polished to ensure an excellent surface finish and corrosion resistance.Q: What are the main benefits of using these tubes in harsh environments?

A: The primary advantages include enviable corrosion resistance, high pressure rating, and significant temperature tolerance (up to 800C), making them ideal for demanding conditions in medical, chemical, and industrial applications.Q: When can custom-sized tubes be delivered?

A: Custom-sized tubes are available upon request, with delivery estimates provided swiftly through quotations. Production time depends on the order specifics, but logistics teams ensure arrival of made-to-order tubes within an optimized schedule.Q: Where are these capillary tubes commonly utilized?

A: These tubes are widely used in medical instruments, laboratories, chemical industry apparatus, and industrial equipment, owing to their splendid reliability and precise manufacturing standards.Q: What surface treatments are offered for these capillary tubes?

A: Customers can choose between hard, annealed, bright polished, and other surface finishes, all of which enhance durability and appearance and suit various environmental requirements.Q: How is the protection of tube ends ensured during transit?

A: Each tube is fitted with plastic end caps, and bundled or boxed packing safeguards the tube ends against damage, ensuring the product arrives intact for usage.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Seamless Steel Pipes Category

High Structural Seamless Steel Pipes

Price 200 INR / Kilograms

Minimum Order Quantity : 20 Kilograms

Color : Gray

Type : Seamless

End Protector : Other, Plastic Caps

Grade : High Structural

Carbon Seamless Steel Pipes

Price 87 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Color : Gray

Type : Other, Seamless Steel Pipes

End Protector : Other, Plastic Caps

Grade : A106 A53 API 5L

Alloy Seamless Steel Pipes

Price 200 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Color : Metallic Gray

Type : Seamless

End Protector : Other, Plastic Caps

Grade : Premium

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS